|

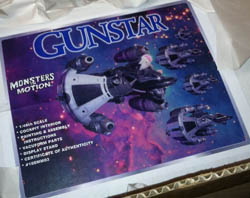

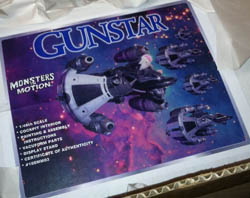

Gunstar

Monsters in Motion

The Last

Starfighter

Parts:

Gunstar

|

cockpit parts

|

|

Stated scale: |

1/48 |

|

Actual scale: |

unverified |

|

Overall length: |

|

Material(s): |

resin |

Number of parts: |

33 gray resin

1 clear vacform canopy

|

Stand included? |

yes |

Decals included? |

no |

My Source: |

Monsters in Motion |

Cost (w/o s&h): |

|

5/19/2014

Greetings, Starfighter!

I guess this has been fallow on the shelves for long enough. Plus, with the

movie turning 30 this year, it seems an appropriate time to take this on. And a

good excuse to watch the movie again.

I've been working on this for about a week and have decided to build this

with lighting. Fortunately the resin is largely hollow-cast so that cuts down on

the drilling, boring, grinding, and cutting needed to run wires and fiber. So

far the lighting scheme includes...

- Engines, of course - diffused white LEDS.

- Gun turrets - there are small red lights in all guns.

- "Headlights" - there are two small red lights in the ship's nose.

- Cockpit - chair arm consoles, fore gunner console and heads-up display

Well, let's back up a go over the story so far.

|

After cleaning the parts with Formula 409 to remove mold release, the main

start to construction was to open up the body, engine pods, and engines for

wiring runs. I used my Dremel with a cutting wheel to open up the body and pods.

I swapped between a drill bit and grinding wheel to open the engines and the

engine attachment point.

The engine aft cowlings are solid resin so for lighting I will have to

drill and bore them out so I can put in a clear insert. After a prolonged parts

box scrounge, I settled on making clear castings of 1/72 SR-71 afterburners.

|

|

The castings are 2ml in volume using a 24-hour epoxy - one of those

craft clear-coats. The slow cure allows bubble-free castings. I've got

time. |

|

With the parts opened up I ran pairs of wires for all 4 engine

mounting points. Another pair of wire runs out through a wiring port at

the base of the lift.

You may notice a lot of grinding went on at

those flanges on the side of the body. That is where the engine pod has

to fit in and the space was too narrow. There was a 1/16" gap between

the pod and body. I ground back those flanges until the pod would fit as

closely as possible to the body. |

![]()

![]()

![]()

![]()

![]()