|

Saladin Class Destroyer

Hermes Class Scout

Scratch/Bash

Franz Joseph

Designs

Star Trek Technical Manual

|

|

Stated scale: |

1/1000 |

|

Actual scale: |

unverified |

|

Overall length: |

|

Material(s): |

styrene / resin |

Number of parts: |

|

Stand included? |

|

Decals included? |

|

My Source: |

|

Cost (w/o s&h): |

|

Working on the PNT

Dreadnought conversion kit got me all bugged up to make the rest of the

Franz Joseph cut'n'paste starships from the old ST Tech Manual. The Destroyer,

Scout, and Transport are simple enough to scratch'n'bash using Polar Lights TOS

1/1000 Enterprise kits. I began by parting out the pieces from three of Polar's E kits.

The details for each build are below but there are a number of things common to

both builds, and to the Dreadnought and the four

Enterprises.

such as deflector dishes and deflector armatures...

No, it's not a small pizza... 9 dishes painted 1:1 Testors copper and Model

Master leather enamel. 3 of the small dishes are for the destroyer, scout, and

transport, 4 for the Enterprises (3 large, 1 small), two small for the

Dreadnought. And one dish to rule them all, one dish to find them, one di...

oops, nevermind.

The armature mount is a bit of heat-stretched styrene

sprue and 0.1" lead shot. I set the shot in clay and drilled a small divot into

it, then superglued the styrene to it. This will be the master for an RTV mold

to make castings.

And on the matter of names and numbers...

Destroyer = U.S.S. Fletcher, NCC-1445, named after the WW-II destroyer

class

Scout = U.S.S. Peddicord, NCC-825, named after the officer-in-charge of the US

Navy's new Scouts and Raider School in 1942.

|

Parts for each ship from the Polar Lights kit are:

- Parts for 1 production

saucer

- Dorsal neck cut away from the 2' hull

- Small deflector dish & spike

- Parts for 1 production warp nacelle.

Parts to be scratchbuilt are the

deflector dish armature. Destroyer will also require some phaser turrets.

|

The only difference between these two builds will be the

extra phasers on the Destroyer. I assembled the saucers with no modifications. Using a

keyhole saw, I cut away the 2' hull from the connecting dorsal neck, then glued

the neck halves together. The aft section of the nacelle has to be rotated 90° to allow the warp grid to

be on the keelside of the project.

I laid the nacelle halves down in a miter box to make the

cut true then used the cut side to mark the cut location for the other nacelle

half. This is best done to each half separately so that the cut

doesn't slant. With the fore and aft nacelle halves glued together I positioned

the rotated end piece in place and cemented it on.

1/16/2011 - Next up - mark & cut the location of the

dorsal neck attachment. I first marked a centerline down the top side of the

nacelle. I measured and drew the neck outline on a piece of tape then laid the

tape over the marked centerline. Next I cut the opening with a Dremel tool

fitted with a cutting wheel and filed it to final shape.

I attached the neck to the saucer, checking to be sure it

fit square to the saucer. Then I aligned and glued the nacelle to the neck and

tweaked its positioning and set the model aside to dry.

A couple other notes - I filled the old nacelle attachment

hole and front intercooler holes with epoxy putty. The aft intercooler holes

will serve to locate the intercoolers. I puttied over the engraved nacelle &

neck panel lines since they're way to big to be correct detail.

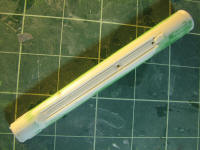

2/7/2011 - puttying, sanding, and filing has been going on

this for a while - and finally de-gapping the seam between the nacelle and the

end-cap. The band of tape protects the end cap ribbing while filling the gap.

This problem is present on all copies of this kit.

2/14/2011 - After lots more sanding, puttying,

re-puttying, and dealing with a gravitic mine impact that broke a nacelle off,

these finally got ready for primer.

2/15/2011 - After installing the deflector armatures,

these went to priming. They have coats of automotive gray on them now. The whole

project is here.

3/1/2011 - One final detail to finally distinguish the

Destroyer from the Scout are the ships phaser blisters.

I had pulled some small RTV putty molds off the

Dreadnought's phasers. I made resin casts of these then broke and sanded away

the flash, leaving just the blisters. I measured for their positions and

superglued them into place on the ships.

Finally I can say: Destroyer on the left, Scout on the

right. The Destroyer has 6 blisters, two pairs topside, one pair below. The

Scout just has one pair below.

On to painting, which is on the whole project page here.

![]()

![]()

![]()

![]()

![]()